At 2 AM on a cold January night in Lansing, Michigan, every second counts as an ambulance speeds toward McLaren Greater Lansing Hospital. But damaged pavement riddled with potholes and cracks slows its approach, turning what should be a quick emergency response into a risky, cautious maneuver.

This situation is more common than many healthcare facility managers realize. Many of them think that a parking lot is just a space for vehicles. But in reality, it’s a critical part of your infrastructure that directly affects patient safety and access to urgent care.

Healthcare facilities in Lansing face unique challenges that go beyond typical commercial properties. With continuous 24/7 operations, heavy emergency vehicle traffic, and vulnerable patients relying on safe access, maintaining your parking areas is paramount. Michigan’s harsh freeze-thaw cycles only accelerate pavement deterioration, making proactive maintenance essential.

This article explores how to develop and apply sealcoating strategies designed to meet the demanding needs of Lansing healthcare facilities, making sure surfaces remain durable, accessible, and compliant with industry standards.

Unique Challenges Healthcare Facilities Face in Lansing

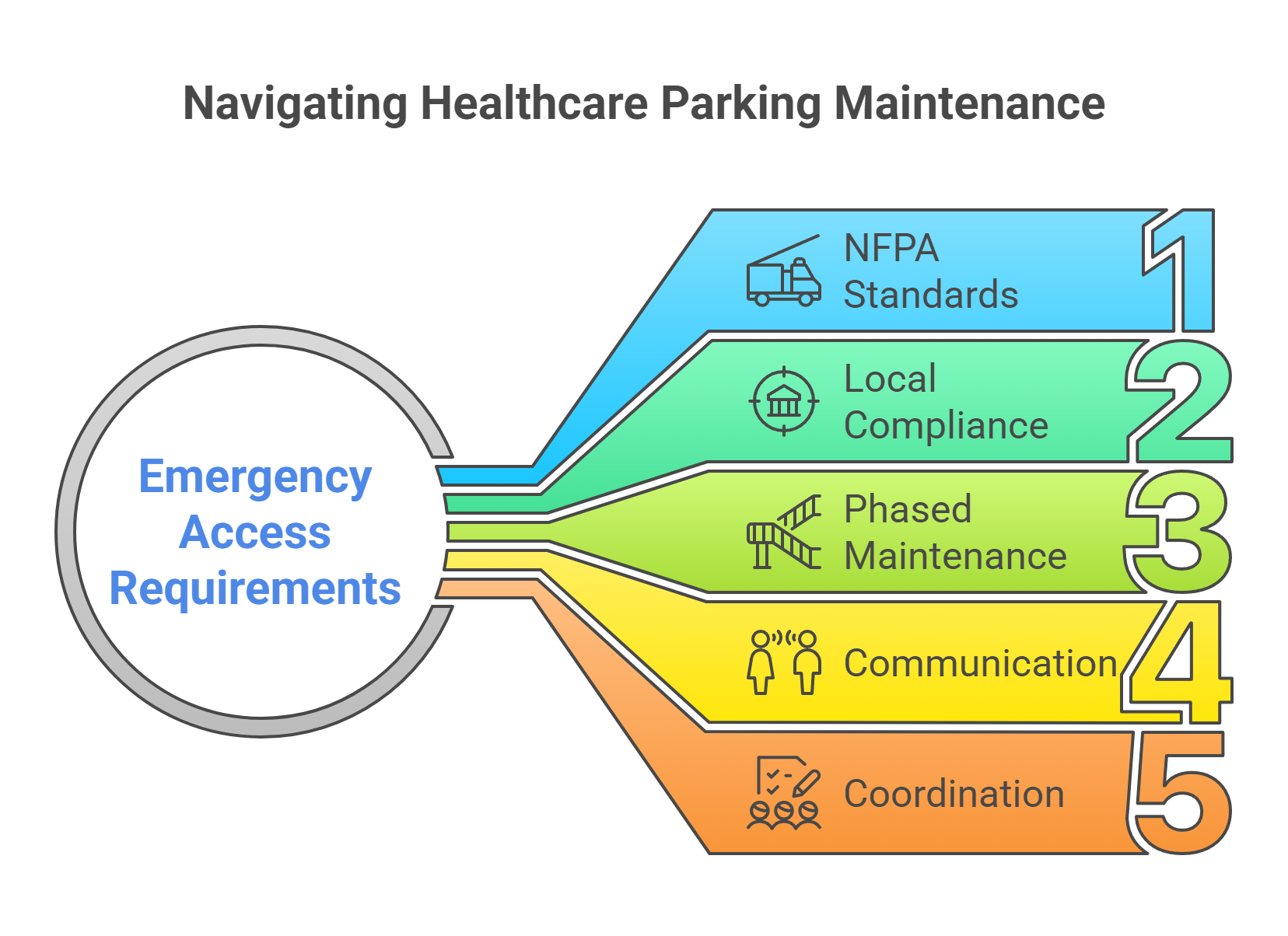

Emergency Access Requirements

Healthcare facilities operate around the clock, meaning parking lot maintenance must be planned with zero interruptions to critical access. Unlike other businesses that can close parking areas temporarily, healthcare providers must ensure continuous access for staff, patients, and especially emergency vehicles.

The National Fire Protection Association (NFPA) enforces strict standards to guarantee facility accessibility for emergency response. According to NFPA codes, every part of a healthcare building must be within 150 feet of a fire apparatus access road. These access routes must be at least 20 feet wide with a vertical clearance of 13.5 feet, and accommodate the turning radius requirements of fire apparatus, typically 25 feet inside and 50 feet outside turning space.

These parameters are important to see to it that emergency vehicles can reach any point of the facility quickly and safely. At the local level, city commissions oversee and approve emergency access compliance to uphold these standards in healthcare parking lots.

This level of access requires careful coordination in sealcoating or other maintenance projects. For example, a major hospital in southeastern Michigan undertook a comprehensive parking lot resealing campaign while maintaining emergency access for its busy trauma center.

The project team staged work in phases, sealing and curing sections sequentially to avoid blocking any emergency routes. Signage and clear detour plans were implemented to guide staff and visitors, while emergency responders were kept informed through regular communication.

Closer to Lansing, McLaren Greater Lansing recently managed a $600 million campus expansion where maintaining unbroken emergency access was a top priority. This was accomplished through close coordination among construction managers, safety officials, and local authorities to ensure fire lanes and access roads remained open throughout the project timeline while accommodating thousands of daily visitors.

These examples illustrate that traditional sealcoating approaches requiring full lot closures are incompatible with healthcare facility demands. Instead, maintenance must be planned with phased execution and adherence to NFPA access standards to guarantee emergency vehicles always have safe, timely routes.

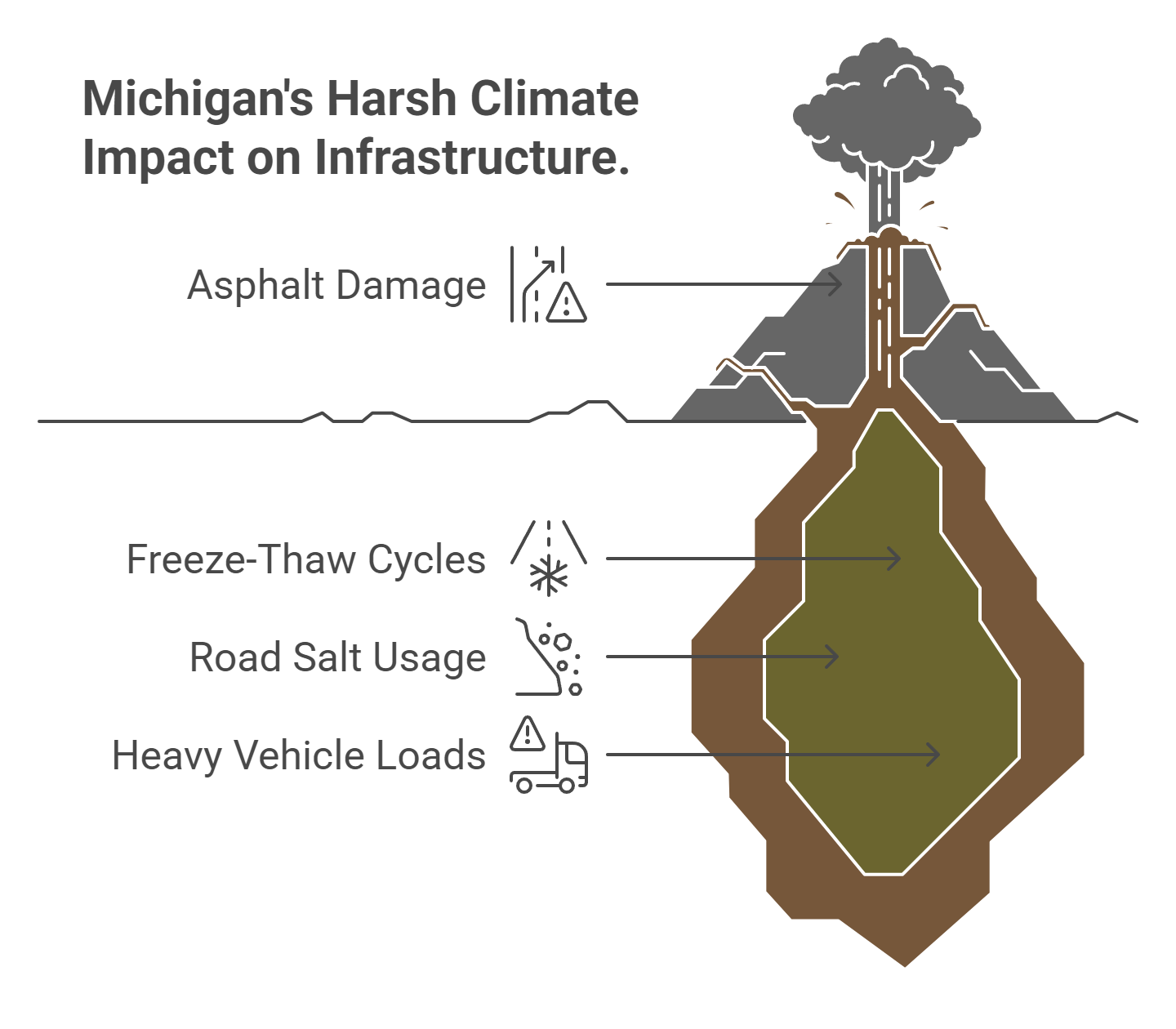

Michigan’s Harsh Climate Impact

Lansing experiences temperature swings from around 16°F in winter to 82°F in summer, with approximately 48-51 inches of annual snowfall and 31-32 inches of precipitation, peaking about 3-5 inches in June.

But it’s not just the cold, it’s the constant freeze-thaw cycles that destroy asphalt. Different seasons bring unique challenges: winter’s snow and ice increase freeze-thaw damage, while summer heat can soften asphalt and worsen cracks, making year-round maintenance essential.

More often than not, water seeps into tiny cracks in your pavement. When temperatures drop, that water freezes and expands by about 9%. This expansion forces the cracks wider. And when it thaws, more water enters. The cycle repeats dozens of times each winter, progressively destroying your pavement structure.

Lansing gets about 59 days of snowfall annually, and Michigan uses approximately 2 million tons of road salt statewide. That salt melts ice as well as chemically attacks your asphalt. Research shows that every $50 worth of road salt can cause about $750 in infrastructure damage. For healthcare facilities with constant emergency vehicle traffic, this chemical assault combines with heavy vehicle loads to accelerate aging dramatically.

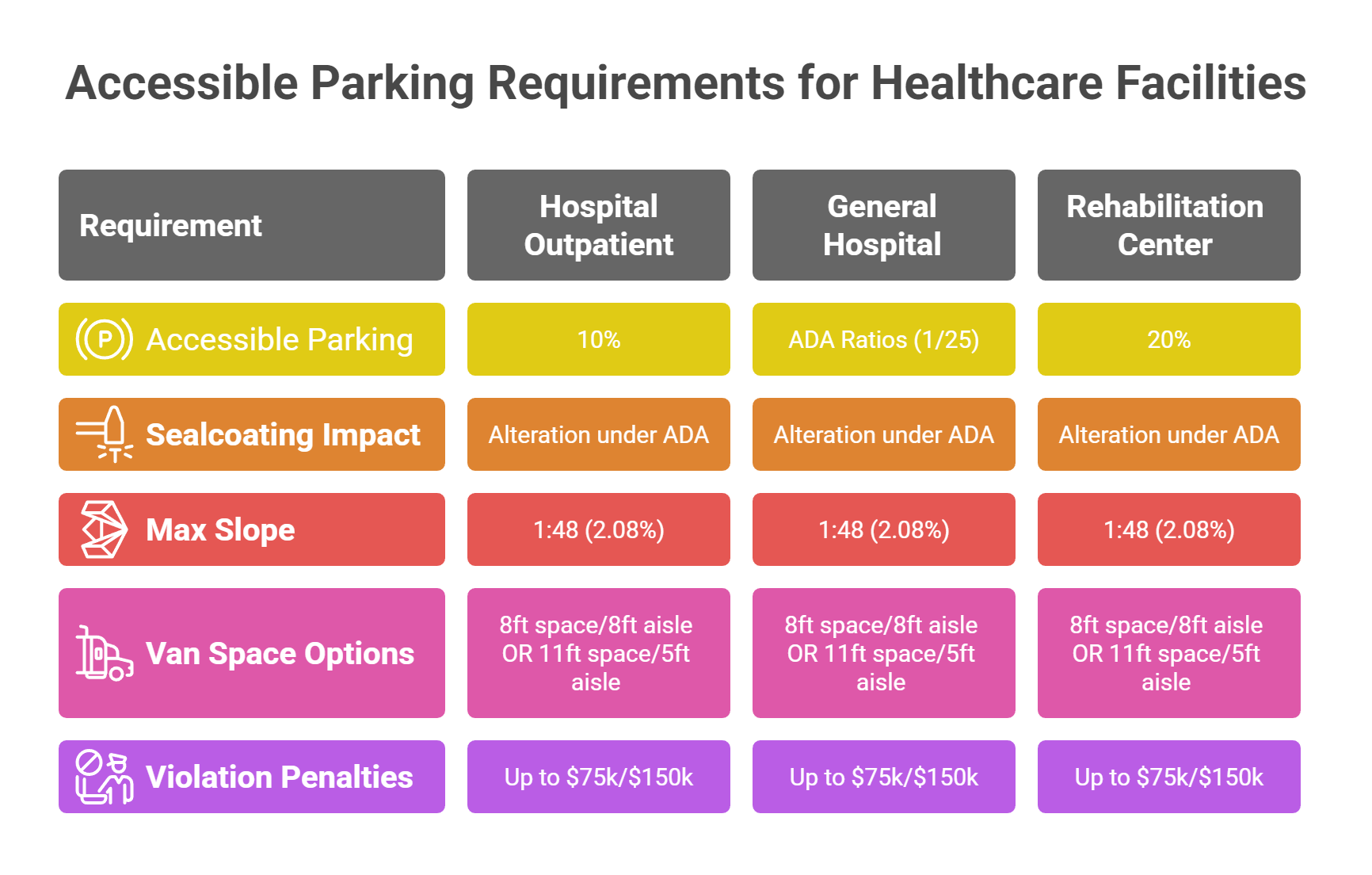

Enhanced ADA Compliance Requirements

Healthcare facilities operate under much stricter accessibility requirements than typical commercial properties. Hospital outpatient facilities require 10% accessible parking, while general hospital areas follow standard ADA (Americans with Disabilities Act) ratios (e.g 1 per 25 spaces). Rehabilitation centres on the other hand need 20%.

But here’s what many facility managers don’t realize: sealcoating constitutes an “alteration” under ADA standards. This means you can’t just maintain your existing layout, you have to bring everything up to current compliance standards, according to the specific legal and regulatory terms set forth for ADA compliance.

However, the slopes are critical. Accessible parking spaces can’t exceed 1:48 (about 2.08%) in any direction. Van-accessible spaces have two options: 8-foot space with 8-foot aisle OR 11-foot space with 5-foot aisle. Get it wrong, and you’re looking at federal penalties up to $75,000 for first violations and up to $150,000 for subsequent violations.

Facing these critical challenges head on? Don’t risk patient safety or operational disruptions. Contact Bart Asphalt’s today for a free, no-obligation assessment of your parking lot and a tailored seal coating strategy that ensures compliance and reliability.

Property Considerations for Healthcare Facility Parking Areas

Traffic Flow and Patient Access

Efficient traffic flow and patient access are foundational to the success of any healthcare facility parking lot in Michigan. A thoughtfully constructed parking area, designed in collaboration with city government and council input, corroborates that patients, staff, and emergency vehicles can move safely and efficiently at all times.

Clear pathways and well-marked driveways are important, especially during the winter season when snow and ice can create hazardous conditions. Regular maintenance and prompt snow removal protect both vehicles and pedestrians, while accessible sidewalks and strategically placed signage guide visitors to their destinations with ease.

Surface Condition Assessment

Conducting a thorough surface condition assessment is an essential step in maintaining a safe and functional parking lot for healthcare facilities. This process involves evaluating the current state of the asphalt, checking for signs of wear such as cracks, potholes, and uneven grading, and noting the overall age and condition of the paving. Special attention should be paid to areas where branches or debris may accumulate, as these can create slip hazards or obstruct pathways.

Drainage and Environmental Factors

Without effective grading, excavating, and paving, water can accumulate on the surface, leading to ice formation in winter and erosion year-round. These conditions not only threaten the integrity of the parking lot but also pose significant safety risks for patients and staff.

When constructing or upgrading parking areas, it’s important to consider environmental factors such as nearby water sources, soil stability, and the impact of tree roots. By designing drainage systems that efficiently channel water away from high-traffic areas, healthcare facilities can prevent water-related damage and maintain a safe, accessible environment for everyone who visits the property.

Strategic Timing for Healthcare Facility Sealcoating

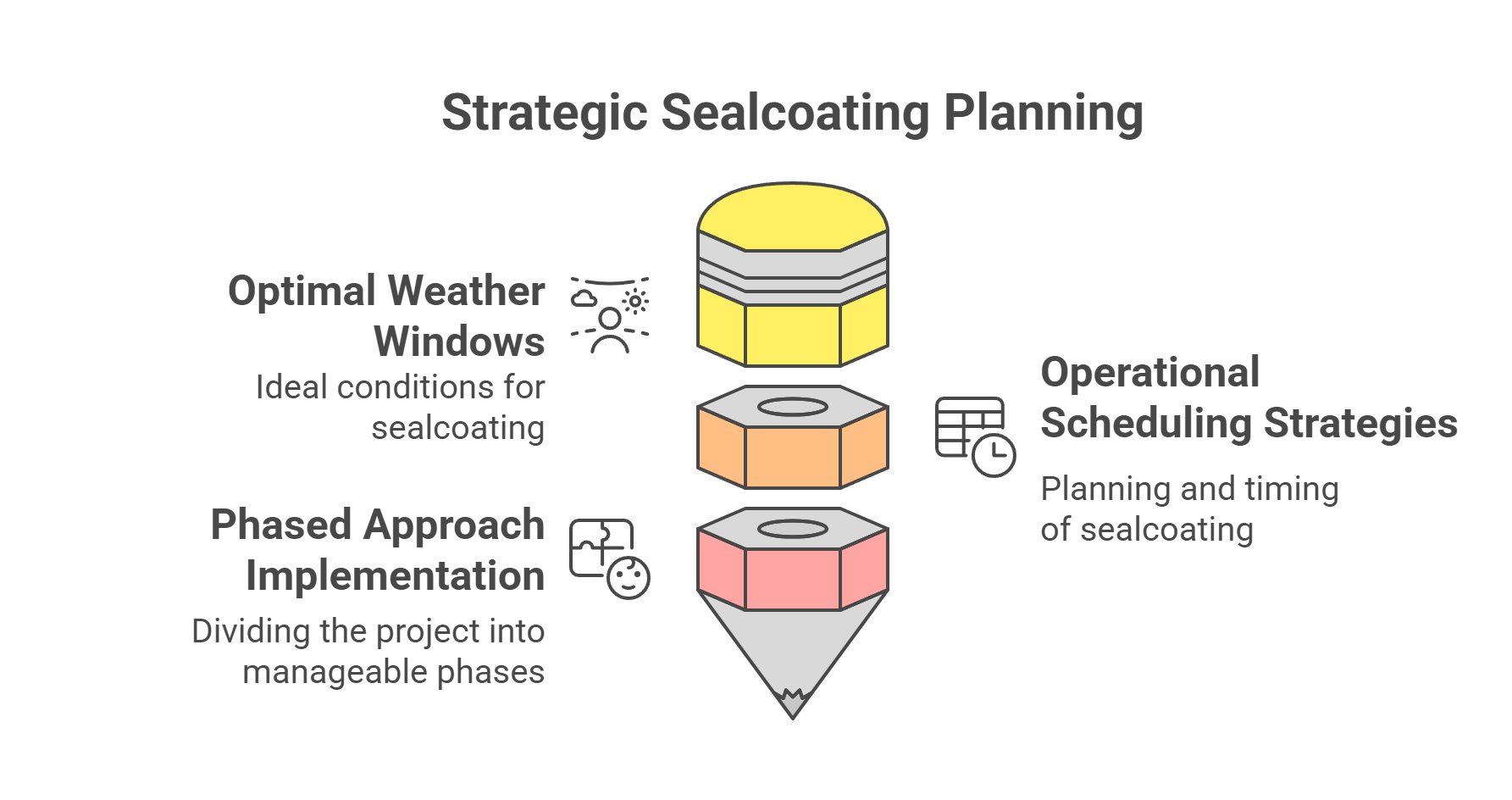

Optimal Weather Windows

Michigan’s sealcoating season typically runs from May through September, but you need consistent temperatures above 50°F, both day and night, for at least 48 hours after application. Ideal conditions range between 75-90°F with low humidity.

Lansing gets about 24 inches of precipitation annually, with peak rainfall in June at over 3.4 inches. This creates a tricky balance, spring offers good temperatures but unpredictable weather. The high humidity in Lansing means you’ll often need to add 2-4 hours to standard cure times.

Operational Scheduling Strategies

Most healthcare facilities find success with overnight work between 10 PM and 6 AM. This minimizes disruption to patient services while allowing work during typically quieter periods. However, you still need to maintain emergency access and accommodate night shift staff.

Start planning 60-90 days in advance. This gives you time to coordinate with local emergency services, arrange temporary parking, set up patient communication systems, and handle any permit requirements.

Phased Approach Implementation

The key to successful healthcare facility sealcoating is phasing that maintains at least 50% of your parking capacity while establishing continuous emergency access. This requires dividing your project into logical zones based on building entrances, service areas, and traffic patterns. In addition, the addition of new phases or steps can further improve the sealcoating process and help maintain operational continuity throughout the project.

Each phase needs its own traffic management plan. Temporary signage must meet ADA requirements and provide clear wayfinding. Digital wayfinding systems can be updated in real-time to guide patients through altered traffic patterns.

Material Selection for Healthcare Environments

Asphalt Emulsion vs. Coal Tar Considerations

Selecting the right sealcoating material is critical for healthcare facilities due to the safety, environmental, and durability demands unique to these settings.

Coal tar sealers have been widely used for their durability and resistance to oil, gasoline, and UV damage. However, they contain high levels of polycyclic aromatic hydrocarbons (PAHs), approximately 1,000 times higher than asphalt-based alternatives, which are harmful to both human health and the environment.

Due to these concerns, several Michigan municipalities have banned coal tar products. Coal tar’s toxicity, carcinogenic potential, and prolonged environmental contamination risks make it less suitable around sensitive healthcare areas, where patient and staff safety are priorities.

In contrast, asphalt emulsion sealers offer a safer and more environmentally friendly option. Modern asphalt emulsions produce significantly lower PAH concentrations, about 65 times less than coal tar, and emit fewer volatile organic compounds (VOCs), aligning better with healthcare sustainability initiatives and minimizing potential indoor air quality impacts near building entrances.

While asphalt emulsions may have a shorter lifespan (typically 2-3 years versus 5+ for coal tar) and are less resistant to oil spills, their flexibility and lower toxicity make them preferable for healthcare parking lot applications where minimizing chemical exposure is essential.

Bio-Based Sealers are emerging as innovative alternatives that further improve environmental safety and sustainability. These sealers use renewable resources such as soybean oil, corn derivatives, or other plant-based oils combined with asphalt to reduce reliance on petroleum-based products.

Bio-based sealers can also lower VOC emissions and the overall carbon footprint of maintenance while maintaining performance suited for moderate to high-traffic areas. Their biodegradability reduces environmental persistence, and ongoing improvements are increasing their durability and weather resistance, making them promising options for healthcare environments seeking greener solutions.

Runoff Prevention and Environmental Controls are equally important considerations. Proper sealcoating strategies for healthcare parking lots include installing permeable or vegetated edges alongside sealcoated areas to reduce erosion and manage stormwater runoff.

These permeable edges help filter pollutants before water drains into municipal systems, mitigating contamination risks associated with sealcoat runoff. Incorporating such best practices supports environmental compliance and protects local ecosystems, a growing concern in Michigan’s regulatory landscape.

Enhanced Durability Requirements

Healthcare facility parking areas demand sealcoating solutions far more robust than those used for typical commercial properties. Constant exposure to heavy vehicles, ambulances, delivery trucks, emergency response units, and high patient turnover creates intense, concentrated wear patterns that standard sealcoating formulations cannot withstand over time.

The repeated force exerted by these large, heavy vehicles subjects pavement surfaces to stress that requires materials specifically engineered for extra durability and resilience.

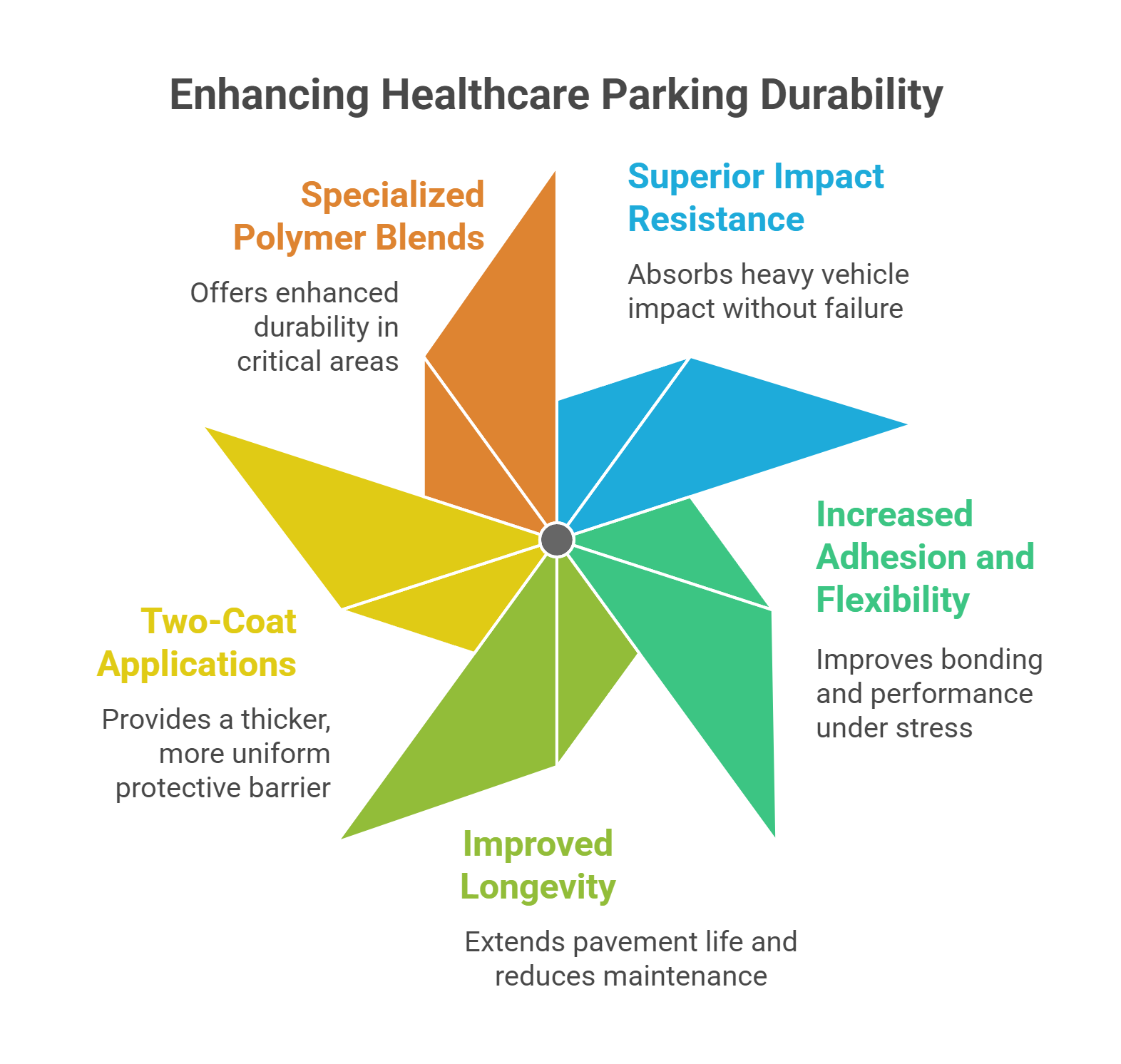

One of the most effective modern approaches to meet these demanding conditions is the use of polymer-modified sealants. These advanced formulations incorporate polymers into traditional asphalt emulsions.

For healthcare facilities, particularly in ambulance approach zones and emergency vehicle staging areas, polymer-modified sealants deliver key benefits:

Superior Impact Resistance: The polymer component significantly increases the sealcoat’s ability to absorb and recover from the dynamic loading of heavy ambulance wheels and emergency vehicles without surface failure.

Increased Adhesion and Flexibility: Improved bonding to the underlying asphalt reduces peeling and improves performance despite frequent heavy use and thermal expansion and contraction.

Improved Longevity: Polymer-modified sealcoats typically extend the functional life of pavement surfaces, lowering maintenance frequency and minimizing disruption to critical healthcare operations.

To maximize protection, healthcare facilities often implement two-coat applications, ensuring a thicker, more uniform barrier against wear and environmental damage. In the most heavily trafficked or critical access areas, formulators may recommend specialized polymer blends or high-solids latex-improved emulsions with solids content of at least 25% to provide even greater durability.

Seal Coating Application Process for Healthcare Facilities

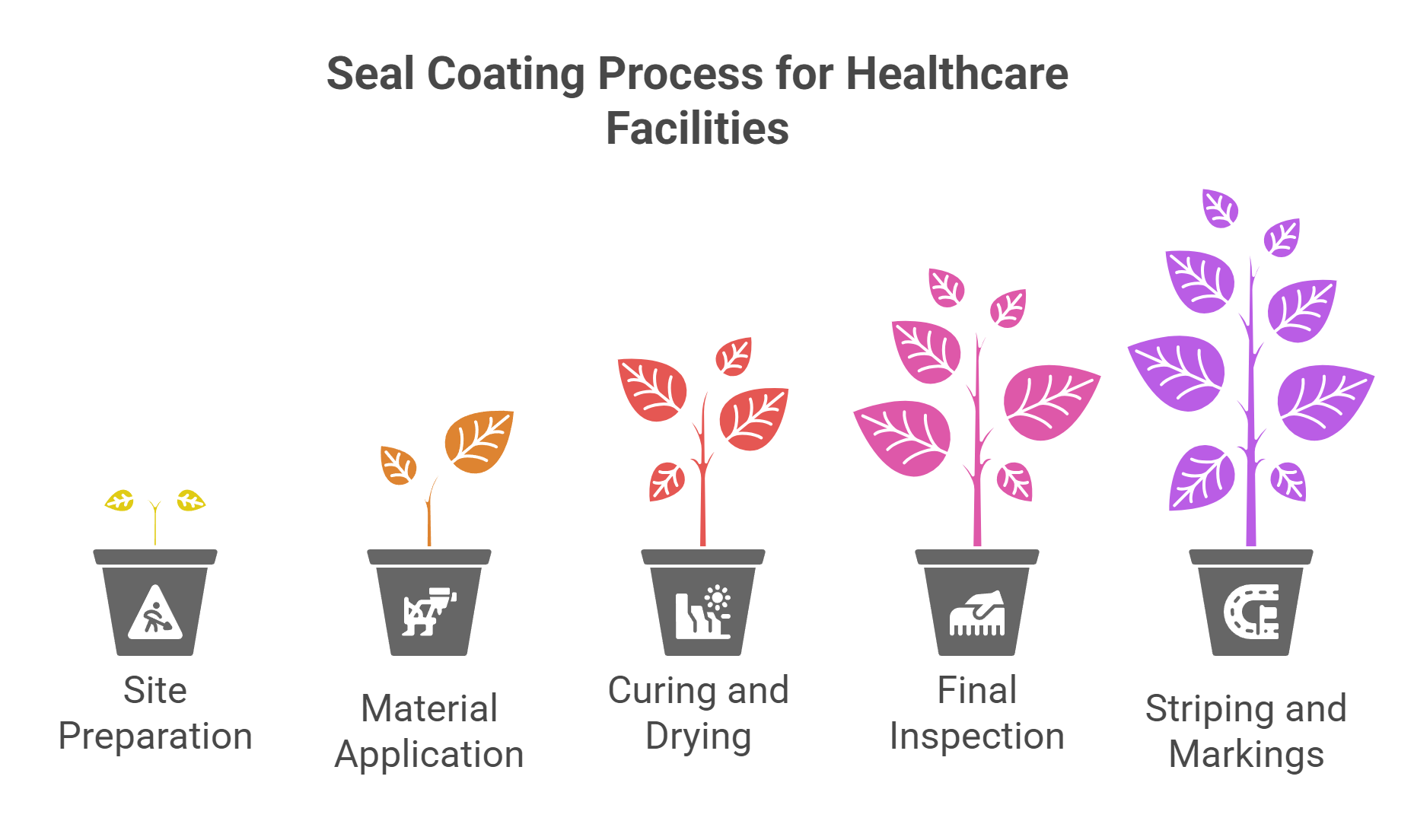

Site Preparation and Cleaning

A successful seal coating project for healthcare facility parking lots begins with meticulous site preparation and cleaning. The process starts with a dedicated team removing all debris, dirt, and loose materials from the asphalt surface to ensure optimal seal coating adhesion. Overhanging branches and nearby foliage are trimmed back to prevent damage and maintain clear access paths.

This not only avoids future maintenance issues but also allows unobstructed movement for workers and emergency vehicles. Any existing pavement damage, such as cracks or potholes, is repaired beforehand to create a smooth, even surface, which is important for long-lasting results.

All vehicles must be relocated, and the entire area clearly marked to prevent unauthorized access throughout the project. Compliance with local regulations and permit requirements remains paramount, often involving oversight from municipal authorities like the city council or mayor’s office.

Material Application

Once the site is fully prepared, the seal coating material is applied using specialized equipment designed to deliver an even, consistent layer over the asphalt. This step requires skilled operators who follow precise techniques to ensure full coverage without excess build-up that could cause uneven surfaces or peeling later.

The type of sealant used is specifically chosen to meet the demands of healthcare environments, with durable formulas that resist heavy traffic and harsh Michigan weather conditions. Multiple thin coats may be applied, allowing each layer to adhere properly before adding the next.

Attention to detail during this stage is essential to ensure the seal coating provides a protective barrier that extends the life of the pavement, prevents water infiltration, and enhances skid resistance for patient and vehicle safety.

Curing and Drying

After application, the seal coating requires adequate curing and drying time, an equally important phase to achieve maximum durability and performance. Healthcare facilities must plan this part of the process carefully to minimize disruption, as parking access may need to be restricted during this period.

Drying times often vary based on temperature, humidity, and product specifications but typically take anywhere from several hours to a full day. During curing, the sealant hardens and bonds with the pavement, forming a resilient, waterproof surface.

It is important that the area remains free of traffic, moisture, and debris throughout this time to avoid compromising the integrity of the newly coated surface.

Final Inspection and Striping

Once the seal coating is fully cured, a thorough final inspection is conducted to ensure the application is uniform, free of defects, and meets all quality standards. Any touch-ups or minor repairs are addressed immediately to guarantee a flawless finish.

After verification, new striping and pavement markings are carefully applied to restore parking lot organization and comply with healthcare facility accessibility standards, including designated spots for handicapped and emergency vehicles.

Cost-Effectiveness and ROI for Healthcare Facilities

Financial Benefits of Proactive Sealcoating

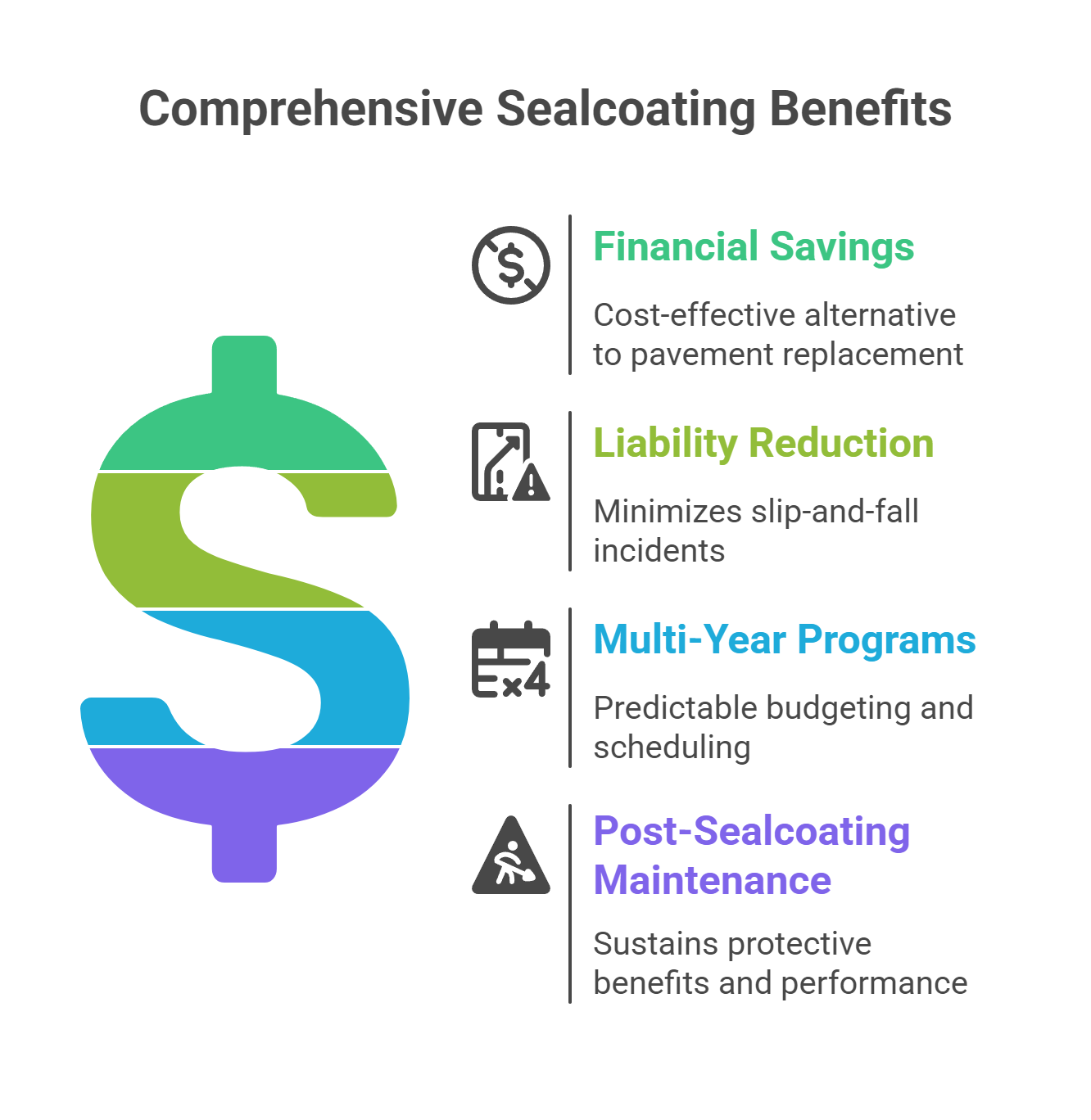

The economics of healthcare facility sealcoating are compelling when you consider the full cost implications. Industry data suggests properly maintained sealcoating programs deliver 200-300% return on investment over pavement lifecycles by extending usable life from approximately 12 years to 25-30 years. Maintaining accurate records of all maintenance activities and expenses is essential for tracking ROI and supporting financial planning decisions.

Current Michigan pricing for professional healthcare facility sealcoating typically ranges from $0.20-$0.50 per square foot, depending on surface condition, accessibility requirements, and project complexity. Compare this to pavement replacement costs of $4.00-$8.00 per square foot, and the value proposition becomes clear.

A typical 100,000 square foot healthcare parking lot costs $20,000-$35,000 to sealcoat versus $400,000-$800,000 for reconstruction. Even accounting for regular maintenance cycles every 2-3 years, you’re looking at net savings of $365,000-$765,000 over a 30-year period.

Beyond direct pavement costs, consider liability reduction benefits. Properly maintained surfaces reduce slip-and-fall incidents that average $20,000-$30,000 per settlement in healthcare environments.

Multi-Year Maintenance Programs

Healthcare facilities gain substantial benefits by establishing multi-year sealcoating agreements instead of handling maintenance as separate, one-off projects. These programs enable predictable budgeting and priority scheduling, which makes sure that maintenance is performed consistently and without unexpected delays.

Additionally, many contractors offer volume pricing under such agreements, often reducing per-square-foot costs by 15–25%, making it a cost-effective strategy for long-term pavement care. Investing in a multi-year program typically delivers returns through reduced emergency repairs, fewer major disruptions, and increased pavement longevity.

Regular sealcoating cycles, typically every 2 to 3 years, also play a major in preventing extensive wear, such as large cracks and potholes, that lead to costly emergency repairs and operational interruptions.

A key advantage of these programs is the development of trusted relationships with contractors familiar with the specific operational demands and regulatory considerations of healthcare facilities.

Post Seal Coating Maintenance

Proper maintenance continues well beyond the initial sealcoat application to sustain protective benefits and pavement performance:

Annual Inspections: Conducting yearly pavement assessments helps identify early signs of wear such as surface cracks, edge deterioration, or drainage issues. Early detection enables timely interventions before minor problems escalate.

Crack Filling Between Seal Coats: Even with regular sealcoating, small cracks can develop over time due to pavement flexing and weather conditions. Filling these cracks promptly prevents water infiltration, which leads to freeze-thaw damage and pothole formation. Scheduled crack repair between sealcoat cycles extends the asphalt’s life and maintains a uniform, safe surface.

Integration with Snow Plowing: In Michigan’s harsh winter climate, snow and ice removal is a constant concern. Coordinating sealcoating maintenance with snow plowing operations is fundamental to avoid damage. Operators should use appropriate plowing techniques and equipment that minimize scraping or gouging of freshly sealed surfaces. Protective sealcoats also help asphalt withstand plowing abrasion, but careful communication with maintenance crews preserves the sealcoat’s durability.

Through well-structured multi-year programs combined with attentive ongoing maintenance, healthcare facilities can maintain parking areas that support operational efficiency, safety, and compliance while maximizing the return on investment in sealcoating.

asphalt sealcoating services Want to unlock 200-300% and slash long-term costs? Reach out to Bart’s Asphalt now to explore customized multi year seal coating programs that deliver predictable budgeting and superior pavement protection for your health care facility.

Emergency Access and Safety Protocols

Fire Department and EMS Coordination

Successful healthcare sealcoating projects require extensive coordination with local fire departments and Emergency Medical Services (EMS). NFPA standards mandate specific access requirements that can’t be compromised during maintenance activities. The legislature often plays a key role in establishing policies or regulations that govern emergency access in healthcare facility parking areas.

Pre-project meetings with emergency officials should cover access route preservation, alternative approach plans, and communication protocols during work periods. Emergency response testing should occur after each project phase to verify that response times aren’t negatively impacted by surface changes or altered traffic patterns.

Since EMS needs real-time updates about access route conditions, surface restrictions, and alternative approaches, communication protocols have become non-negotiable. Many facilities establish dedicated communication channels with dispatch centers during maintenance periods.

Patient Safety During Maintenance

Healthcare patients represent vulnerable populations requiring special considerations during maintenance activities. It is essential to plan safety measures that address the needs of patients of all ages, as age demographics can influence vulnerability and response to environmental changes.

Dust control becomes fundamental for patients with respiratory conditions. Chemical exposure must be minimized, particularly near building entrances and patient drop-off areas.

Wayfinding and signage take on added importance when serving patients who may have mobility limitations, visual impairments, or cognitive challenges. That’s why staff communication protocols ensure that patient transport teams, security personnel, and clinical staff understand altered traffic patterns and any temporary restrictions.

How Bart’s Asphalt Serves Lansing Healthcare Facilities

Specialized Healthcare Experience

Bart’s Asphalt has developed specialized expertise serving healthcare facilities throughout Michigan. Our team understands the unique operational requirements that distinguish healthcare properties from standard commercial applications. We’ve successfully completed projects for hospitals, outpatient centers, rehabilitation facilities, and specialty clinics while maintaining full operational continuity.

Our healthcare portfolio includes experience with 24/7 operational coordination, emergency access preservation, and complex phasing strategies that maintain patient services throughout maintenance periods.

The successful execution of these maintenance projects involves coordination among various persons, including property owners, facility managers, and other parties in interest.

Michigan Climate Expertise

Local weather pattern knowledge provides significant advantages for our healthcare facility projects where timing is of utmost value. Our team monitors extended forecasts and maintains flexible scheduling systems that adapt to Michigan’s unpredictable weather while coordinating with healthcare operational requirements.

We specify formulations that have proven performance in Michigan healthcare environments rather than relying on generic solutions that may not withstand local conditions. Also, we consider the height of parking areas to establish proper drainage and address weather-related challenges specific to the site’s topography.

Comprehensive Service Approach

Assessment and planning services for healthcare facilities include operational impact analysis, regulatory compliance review, and custom phasing strategies that maintain continuous access.

Our pre-project planning process addresses the complex requirements that distinguish healthcare properties from other commercial facilities, with a focus on evaluating and managing land parcels to verify proper assessment and integration into project planning.

On the other hand, phased project implementation maintains emergency access while providing high-quality surface restoration. Emergency response capabilities include 24/7 availability, rapid response protocols, and immediate problem resolution systems.

Getting Started with Your Healthcare Facility Sealcoating Project

Initial Assessment and Planning

As you might have noticed, every successful healthcare sealcoating project starts with a thorough evaluation that considers both pavement condition and facility operations. Bart’s Asphalt offers complimentary parking lot condition assessments tailored specifically for healthcare environments.

These evaluations include a detailed inspection of surface integrity, drainage effectiveness, emergency access compliance, and ADA accessibility. Plus, operational analyses review patient flow, emergency vehicle routes, staff parking demands, and visitor accessibility, helping to develop realistic project timelines that balance maintenance needs with ongoing facility activity.

While Bart’s Asphalt specializes in healthcare parking lot sealcoating, it’s important for facility managers to ensure any contractor they choose has specific experience working within healthcare settings.

This expertise is important for understanding regulatory requirements, minimizing operational disruptions, and addressing the unique safety concerns of vulnerable patient populations.

Implementation Strategy Development

A well-crafted implementation plan customizes phasing and sequencing to your facility’s operational rhythms, prioritizing uninterrupted emergency access throughout all project stages. Coordinated efforts with local fire departments and EMS services form an essential part of the strategy, guaranteeing that emergency response capabilities are preserved at every step.

Clear communication protocols form the backbone of successful projects, establishing structured coordination among facility management, clinical teams, security personnel, emergency responders, and contractors. This transparency ensures rapid resolution of any issues and maintains safety and efficiency during maintenance activities.

Long-Term Maintenance Planning

Preventive maintenance extends the life and effectiveness of your sealcoating investment. Regular inspections and systematic care identify emerging pavement issues early, allowing timely repairs that prevent costly emergencies and preserve patient safety and access.

Sound budget forecasting supports facility financial planning, with multi-year maintenance agreements offering advantages such as volume pricing discounts, priority scheduling, and cost predictability that align with long-term goals.

Choosing the Right Contractor: Key Considerations

Selecting a sealcoating contractor is a vital step that can greatly impact the success of your healthcare facility’s maintenance program. In addition to healthcare-specific experience, consider the following criteria:

Proven Track Record: Look for contractors with documented experience in similar healthcare projects, including references and completed case studies.

Regulatory Knowledge: The contractor should be well-versed in applicable NFPA, ADA, and local municipal regulations to ensure compliance throughout the project.

Safety and Communication: Evaluate their commitment to safety protocols and their ability to maintain clear communication with all stakeholders.

Materials and Techniques: Confirm they use sealcoating materials and application methods suited to the demands of healthcare environments, such as polymer-modified sealants or phased application strategies.

Flexibility and Responsiveness: The contractor should demonstrate flexibility to adapt schedules as needed and responsiveness to address unexpected challenges without compromising access.

Protecting Your Healthcare Facility Investment

Healthcare facilities in Lansing face unique challenges that require specialized sealcoating strategies going far beyond standard commercial maintenance. From the view of a healthcare administrator, strategic sealcoating offers a clear perspective on how well-maintained parking infrastructure directly supports critical missions, emergency response, patient care, and accessibility that can’t be compromised by poor maintenance decisions or inadequate planning.

The combination of Michigan’s harsh climate, strict regulatory requirements, and 24/7 operational demands creates maintenance challenges that require specialized expertise and proven strategies. But with proper planning, material selection, and execution, sealcoating becomes a powerful tool for protecting your infrastructure investment while supporting your healthcare mission.

Strategic sealcoating programs deliver exceptional value through extended pavement life, reduced liability exposure, predictable maintenance costs, and most importantly, reliable infrastructure that supports patient care and emergency response capabilities regardless of weather conditions or operational demands.

The key to success lies in partnering with contractors who understand healthcare facilities’ unique requirements and have demonstrated experience managing complex projects that maintain operational continuity while delivering high-quality results. At Bart’s Asphalt, we’ve built our reputation on exactly this type of specialized expertise.

Your patients, staff, and emergency responders deserve parking infrastructure that works reliably in all conditions. Let us help you achieve that goal through proven strategies developed specifically for Michigan healthcare facilities.

Protect your patients, staff and mission with infrastructure that never fails. Contact Bart’s Asphalt immediately for a personalized seal coating plan designed for Lansing healthcare facilities.