Did you know that Michigan’s harsh winters and relentless freeze-thaw cycles can silently sabotage your commercial asphalt surfaces? Without proper care, cracks and potholes are almost inevitable.

But don’t worry. By the time you finish this guide, you’ll be equipped with expert paving strategies and practical tips specifically tailored to Michigan’s challenging climate. These insights will help you protect your asphalt investment and avoid expensive repairs.

So, if you’re ready to take control of your commercial paving, let’s get into everything you need to know to keep your asphalt in top shape.

Key Takeaways

- Michigan’s climate necessitates specialized asphalt maintenance to prevent damage from freeze-thaw cycles and weather conditions, helping maintain safety and property value.

- A comprehensive maintenance plan should include preventive, corrective, and advanced restoration techniques, combined with seasonal inspections to identify and address issues early.

- Investing in regular maintenance can greatly reduce long-term costs, with proactive measures yielding substantial savings compared to reactive repairs or complete asphalt replacements.

Why Michigan Commercial Properties Need Specialized Asphalt Care

Michigan’s climate poses some serious challenges for commercial asphalt, as harsh winters coupled with frequent freeze-thaw cycles accelerate cracks, potholes, and other damages that can quickly undermine pavement integrity.

For example, if a retail complex continues to ignore regular maintenance for several seasons, what started as minor cracks can rapidly expand into costly potholes, forcing an unexpected full replacement that sets the owners back over thousands of dollars.

You might be wondering why such specialized care is important beyond just the weather. Well, maintaining commercial asphalt transcends beyond durability. It’s also a legal necessity. Regular upkeep makes sure your property complies with safety regulations and ADA accessibility standards, protecting your business from potential liabilities. Specialized commercial asphalt services tailored for Michigan’s climate are essential to address these unique challenges and ensure long-lasting pavement performance.

The thing is: investing between $300 and $1,000 a year on basic maintenance can spare you the staggering expense of a complete overhaul, which can climb upwards of $75,000. This proactive strategy keeps your asphalt functional, attractive, increases tenant satisfaction, and increases the overall property value.

Of course, because of Michigan’s tough environment, a one-size-fits-all approach simply won’t cut it. But with the right care plan tailored to local conditions, commercial property owners and local businesses can keep their asphalt surfaces safe and professional-looking season after season.

Essential Asphalt Maintenance Services for Michigan Businesses

To extend the lifespan of your commercial asphalt surfaces, understanding the essential maintenance services is important. These services can be categorized into three main types: preventive maintenance, corrective maintenance, and advanced restoration techniques.

Each category addresses different aspects of asphalt care, ensuring comprehensive coverage for your property.

Let’s take a look at them in more detail:

Preventive Maintenance Services

For any effective asphalt maintenance plan to succeed, preventive maintenance must be at the forefront. At the base of this is asphalt sealcoating, which is recommended every 2-3 years to protect the asphalt from weather damage and preserve its structure and appearance.

This process involves applying a protective layer over the asphalt surface, which shields it from water, UV rays, and other damaging elements.

Another measure to consider is the crack filling and sealing, which are not to be overlooked because of freeze-thaw cycles. Lastly, seasonal inspections should be taken seriously as it assist in identifying surface issues at an early stage, making it easier to manage and budget for repairs.

Corrective Maintenance Services

Corrective maintenance is all about addressing existing damage to your asphalt surfaces. One of the most common issues is potholes, which must be repaired promptly to prevent further deterioration. Patching and the ability to patch potholes quickly are crucial aspects of corrective maintenance, as they ensure the surface remains safe, durable, and visually appealing.

Another one is the line striping and marking maintenance services, with benefits such as:

- compliance with local regulations,

- traffic flow improvement within your commercial property,

- effective drainage solutions.

Advanced Restoration Techniques

For more extensive repairs, advanced restoration techniques like asphalt milling services and infrared repair offer cost-effective and efficient solutions as part of a complete asphalt repair solution for commercial properties. Asphalt milling involves removing the top layer of the asphalt surface and recycling it, which is both sustainable and budget-friendly.

Infrared repair technology, on the other hand, minimizes business disruption during repairs. This process uses infrared heat to seamlessly blend new asphalt with existing surfaces, resulting in a smooth and durable repair.

Michigan Climate Considerations and Seasonal Planning

The frequent freeze-thaw cycles can cause asphalt surfaces to expand and contract, leading to cracks and other damage. To combat this, it is important to incorporate seasonal planning into your asphalt maintenance strategy.

This includes:

- Winter preparation to protect against ice and snow.

- Spring damage assessments to identify and repair winter damage.

- Summer optimization to manage heat-related issues.

Planning for these seasonal changes allows contractors to work efficiently and minimize downtime, ensuring that your asphalt surfaces remain in top condition year-round.

Winter Preparation and Protection

Important steps for winter preparation include:

- Pre-winter crack sealing,

- Sealing cracks,

- Following snow removal and de-icing best practices to preserve asphalt integrity during the winter months.

Spring Damage Assessment

As the snow melts and temperatures steadily rise, spring becomes the ideal time to give your asphalt a careful once-over. A thorough inspection helps spot any new cracks, potholes, or surface damage that winter’s freeze-thaw cycles may have caused.

Plus, early spring is perfect for checking water pooling, which is an important clue that your drainage system needs attention.

To keep your pavement in prime condition, Safe Seal recommends these practical steps:

- Start by clearing away salt residues and debris that can accelerate asphalt deterioration.

- Use a measuring tool or straight edge to assess crack widths. Cracks wider than 1/4 inch warrant prompt filling to halt expansion.

- Pay close attention to spots where water lingers after rain or melting snow. Standing water weakens asphalt and can lead to potholes.

- Evaluate the effectiveness of your drainage systems, ensuring gutters, drains, and slopes direct water away from the pavement surface.

- Schedule repairs for damage found during your inspection as soon as weather permits. Waiting risks worsening damage and costlier fixes down the line.

Keep in mind, timing is everything. Spring repair work is most successful when temperatures consistently stay above 50°F, allowing repair materials to properly set and bond. Therefore, planning repairs for late spring can maximize outcomes and durability.

Summer Optimization

Summer presents its own set of challenges for asphalt maintenance. The heat can exacerbate existing pavement issues, making regular maintenance very important.

Sealcoating should be performed during dry periods to strengthen effective adhesion and protection. Likewise, planning major asphalt projects for cooler times of the day can reduce heat-related strain during application.

Managing heavy traffic during peak business seasons is also important to avoid damage to the asphalt surface. Scheduling maintenance and repairs during off-peak hours minimizes disruption to your business and ensures that your asphalt surfaces remain smooth and functional.

Importance of Drainage in Asphalt Maintenance

Proper drainage is a cornerstone of effective asphalt maintenance for both commercial and residential properties. Without adequate drainage, water can accumulate on the surface of your asphalt parking lot, driveway, or roadway, leading to erosion, premature deterioration, and even structural damage. These drainage issues not only result in costly repairs but can also compromise safety and diminish the curb appeal of your property.

For commercial asphalt paving projects in Southeast Michigan, where weather conditions can be especially harsh, prioritizing drainage is essential. Water that pools on the surface or seeps into cracks can quickly undermine the base layers of your pavement, causing cracks to widen and potholes to form. Over time, this can lead to the need for extensive asphalt repairs or even full resurfacing—both of which are far more expensive than proactive maintenance.

To prevent these problems, property managers and business owners should schedule regular inspections as part of their ongoing asphalt maintenance plan. Experienced asphalt contractors can assess your existing asphalt parking lot or driveway for signs of poor drainage, such as standing water, soft spots, or visible erosion. They can then recommend high quality paving solutions, such as slope grading, installation of functional drainage systems, or targeted repairs, to keep water moving away from your pavement.

In addition to structural solutions, routine maintenance services like asphalt sealing and crack filling play a vital role in protecting your asphalt investment. By sealing the surface and filling cracks, you help prevent water from penetrating the pavement, reducing the risk of costly repairs down the line. Asphalt line striping and clear pavement markings can also help direct water flow and improve safety for both vehicles and pedestrians.

For businesses and local property managers in Michigan, working with a reputable asphalt contractor ensures that drainage is never overlooked. A comprehensive maintenance plan should include regular inspections, prompt repairs, and ongoing maintenance services tailored to the unique needs of your property. This proactive approach not only extends the life of your asphalt but also delivers cost savings, improved safety, and enhanced curb appeal.

Whether you’re managing a commercial parking lot, a residential driveway, or municipal roadways, effective drainage is key to maintaining durable, long-lasting asphalt surfaces. By addressing drainage issues early and investing in ongoing maintenance, you protect your property, reduce the risk of costly repairs, and ensure that your asphalt surfaces remain safe, functional, and visually appealing year-round.

Cost Analysis and ROI for Michigan Commercial Properties

Strong asphalt maintenance is a strategic move that can save commercial property owners substantial money and headaches in the long term. Understanding the costs attached to different services, along with the return on asphalt investment (ROI), empowers decision-makers to allocate budgets wisely and protect their properties effectively. Choosing a contractor who completes each job with professionalism and attention to detail ensures that your investment delivers lasting value.

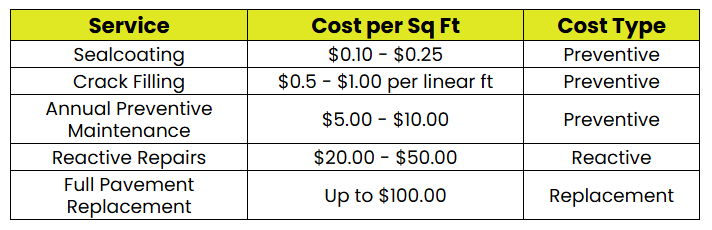

To clarify the stakes, here’s a breakdown of typical maintenance expenses across Michigan and how proactive care compares to reactive fixes.

Service-by-Service Cost Breakdown

Sealcoating prices typically range from $0.14 to $0.25 per square foot for smaller commercial lots, with larger areas costing between $0.10 and $0.18 per square foot. Crack filling, an essential measure to halt water penetration, usually costs between $0.50 and $1.00 per linear foot.

This difference in investment clearly shows its impact: proactive maintenance like these services generally falls between $5 and $10 per square foot annually. Conversely, reactive repairs can spiral into the $20 to $50 range, and a full pavement replacement may top out at $100 per square foot.

Clearly, investing in a regular maintenance program stretches your asphalt’s lifespan and increases safety and curb appeal. Along with cost savings, this approach reduces the risk of unexpected surface failures that can disrupt business operations or pose hazards to customers and tenants.

Michigan Compliance and Quality Standards

Adhering to Michigan’s compliance and quality standards is essential for any commercial asphalt project. The Michigan Department of Transportation (MDOT) provides comprehensive guidelines for construction material quality and performance, ensuring that all asphalt projects meet the necessary standards. While concrete is known for its long-lasting durability and strict installation requirements, asphalt is often chosen for its flexibility, affordability, and suitability for Michigan commercial properties.

This section will delve into the specifics of MDOT-approved materials and standards, as well as safety and environmental compliance protocols.

MDOT-Approved Materials and Standards

MDOT-approved materials and standards play an important role in establishing the durability and performance of asphalt surfaces. Specific asphalt mix designs are mandated for use in MDOT projects for structural integrity and longevity.

Quality assurance requirements for commercial projects include:

- Regular testing and inspection of materials to meet MDOT’s stringent standards.

- Ensuring that asphalt surfaces can withstand the harsh Michigan climate and heavy traffic loads.

- Using MDOT-approved materials to provide durable asphalt surfaces that offer long-term performance and reliability.

Adhering to these guidelines can help property managers be confident that their asphalt projects will deliver high-quality results that stand the test of time.

Safety and Environmental Compliance

In commercial asphalt projects, protecting both people and the environment ranks among the highest priorities. That’s why designing ADA-compliant parking lots is more than meeting legal requirements, but about creating spaces that truly welcome everyone, including individuals with disabilities.

This involves clear signage, accessible routes, and firm, slip-resistant surfaces that make moving around safe and convenient. Regular audits help confirm that these standards are being met, stimulating a welcoming and secure environment for all visitors.

Shifting focus to environmental stewardship, the modern approach to asphalt projects places a strong emphasis on sustainability. Contractors actively reduce emissions by selecting low-VOC sealants and implementing recycling programs that reuse materials such as asphalt millings.

Techniques like permeable pavements and bio-retention systems manage stormwater effectively, safeguarding nearby ecosystems.

Worker and public safety also come under careful scrutiny. Comprehensive safety training forms the backbone of protecting personnel, along with the consistent use of personal protective equipment (PPE) such as helmets, gloves, safety glasses, and high-visibility clothing.

Taken together, these measures reflect a genuine commitment to ethical and responsible practices that benefit workers, the community, and the environment alike.

Selecting the Right Michigan Asphalt Contractor

With numerous contractors available across Michigan, it’s important to choose one that meets all the necessary qualifications and has experience in handling commercial projects, as well as industrial properties such as manufacturing plants and industrial complexes.

What are these requirements, and why do they matter so much? Let’s find out below.

Essential Contractor Qualifications

Contractors must hold a valid builder’s license and have general liability insurance with at least $1 million coverage. This ensures that the contractor is qualified to perform the work and provides financial protection in case of any issues.

Experience with commercial properties and climate challenges is another critical factor. Commercial projects differ significantly from residential work, requiring an experienced team with specialized knowledge and skills.

Quality contractors maintain modern, well-maintained equipment and utilize top-grade materials that adhere to Michigan DOT standards. This ensures that the work is completed efficiently and to the highest quality workmanship.

Additionally, having emergency response capabilities is important, especially in Michigan’s harsh climate. Contractors should be able to respond quickly to any issues that arise, minimizing downtime and guaranteeing the safety and functionality of the asphalt surfaces.

Regional Contractor Comparison

Michigan is divided into distinct regions, each with its own challenges and specialties when it comes to asphalt maintenance. Contractors in southeast Michigan, such as those in the Detroit and Ann Arbor areas, often focus on high-density commercial projects and urban environments.

These contractors are experienced in handling the unique needs of busy commercial areas.

Meanwhile, in West Michigan, including the Grand Rapids and Kalamazoo regions, contractors often emphasize environmental and aesthetic considerations in their services for large-scale projects. This region is known for its focus on sustainability and visually appealing projects.

Mid Michigan providers, covering areas like Lansing and Flint, balance urban and rural projects, addressing the diverse needs of different communities.

Northern Michigan contractors, serving areas like Traverse City and Petoskey, face unique challenges related to the harsher climate and need specialized knowledge for project execution.

Vetting Process and Questions to Ask

The vetting process is just as important as other steps for selecting the right asphalt contractor. Start by reviewing the contractor’s portfolio and checking references to assess their previous work and customer satisfaction. This will give you an idea of their expertise and reliability.

Confirm pricing transparency by requesting detailed quotes that outline all costs associated with the project, including a free estimate. This helps avoid any unexpected expenses and guarantees that you are fully aware of what you’re paying for.

Following these steps and asking the right questions helps you select a contractor that meets your needs and delivers high-quality results.

Summary

Maintaining commercial asphalt in Michigan requires a forward-thinking approach that addresses the unique challenges of the state’s climate. With regular preventive care, seasonal inspections, and timely repairs, you extend the lifespan of your pavement while keeping safety, accessibility, and property value at the forefront.

When it comes to trusted asphalt solutions, Bart’s Asphalt stands out with a full spectrum of services, from sealing and crack filling to major repairs and resurfacing, all customized for Michigan’s conditions. We provide comprehensive paving and maintenance solutions for commercial properties, ensuring long-term safety, curb appeal, and operational efficiency. Our experts combine local experience with industry-leading techniques to deliver results that last.

Take the first step toward safeguarding your investment today. Reach out to us and discover how we can keep your pavement strong and inviting all year long.

Frequently Asked Questions

Why is preventive maintenance important for asphalt surfaces in Michigan?

Preventive maintenance is important for asphalt surfaces in Michigan to mitigate the effects of the harsh climate and freeze-thaw cycles, consequently extending their lifespan. Regular practices like sealcoating and crack filling help avert minor issues from escalating into costly repairs.

How often should sealcoating be done for commercial properties in Michigan?

For commercial properties in Michigan, sealcoating should be done every 2-3 years to effectively protect the asphalt from weather damage and maintain its condition.

What are the key qualifications to look for in an asphalt contractor?

The key qualifications to look for in an asphalt contractor are a valid builder’s license, general liability insurance, relevant experience with commercial projects, and the use of modern equipment that meets state standards.

How does proactive maintenance compare to reactive repairs in terms of cost?

Proactive maintenance is notably more cost-effective than reactive repairs, with annual costs averaging $5 to $10 per square foot, compared to $20 to $50 for repairs and up to $100 for complete replacements.

What should be included in an emergency response plan for asphalt maintenance?

An effective emergency response plan for asphalt maintenance should include protocols for prioritizing urgent repairs, contractor contact information, and strategies for ensuring business continuity, such as alternate access routes to minimize disruption.